high quality slurry pump india factory

Latest articles

If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

high quality slurry pump india factory...

high quality slurry pump india factory 【high quality slurry pump india factory】

Read MoreIf centrifugal, are the impellers of the right design and material?

high quality slurry pump india factory...

high quality slurry pump india factory 【high quality slurry pump india factory】

Read MoreWA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

high quality slurry pump india factory...

high quality slurry pump india factory 【high quality slurry pump india factory】

Read MoreSlurry Pump

high quality slurry pump india factory...

high quality slurry pump india factory 【high quality slurry pump india factory】

Read MoreSlurry Pump

high quality slurry pump india factory...

high quality slurry pump india factory 【high quality slurry pump india factory】

Read MoreHow much solids damage can the customer tolerate?

high quality slurry pump india factory...

high quality slurry pump india factory 【high quality slurry pump india factory】

Read MoreWhat we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. , Slurry pumps, are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

high quality slurry pump india factory...

high quality slurry pump india factory 【high quality slurry pump india factory】

Read More1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

high quality slurry pump india factory...

high quality slurry pump india factory 【high quality slurry pump india factory】

Read MoreIf a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

high quality slurry pump india factory...

high quality slurry pump india factory 【high quality slurry pump india factory】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

high quality slurry pump india factory...

high quality slurry pump india factory 【high quality slurry pump india factory】

Read More

Popular articles

- A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

- Fine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

- Slurry pumps can be used for.

- All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

- Types of slurry pumps

- With the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

Latest articles

-

factors-to-consider-when-choosing-a-slurry-pump

-

Dredge Pump

-

As new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

-

TL FGD Pump

-

Slurry Pump

-

What is the best seal arrangement for the application?

Links

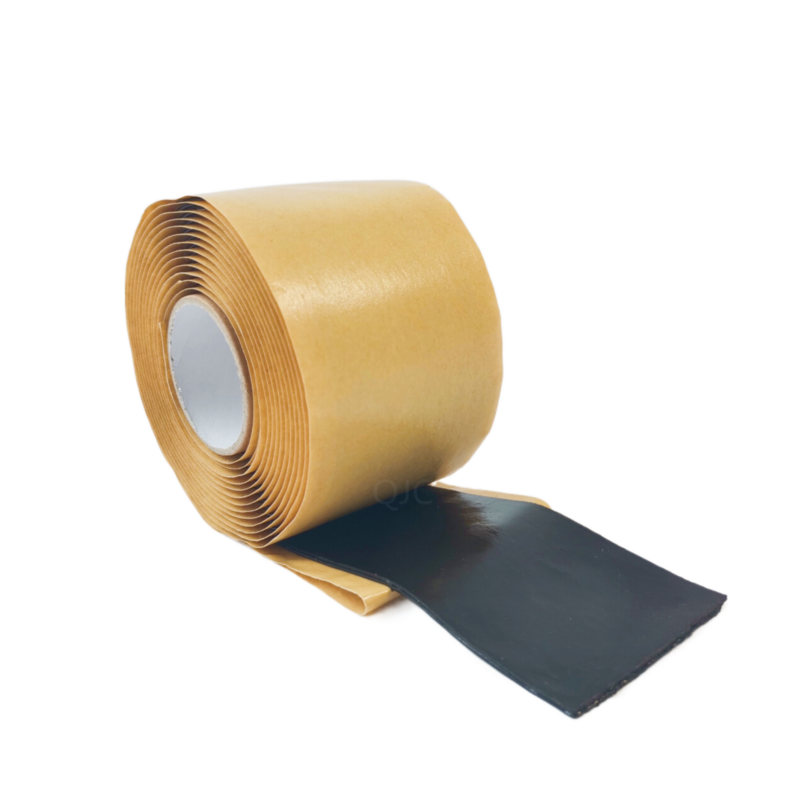

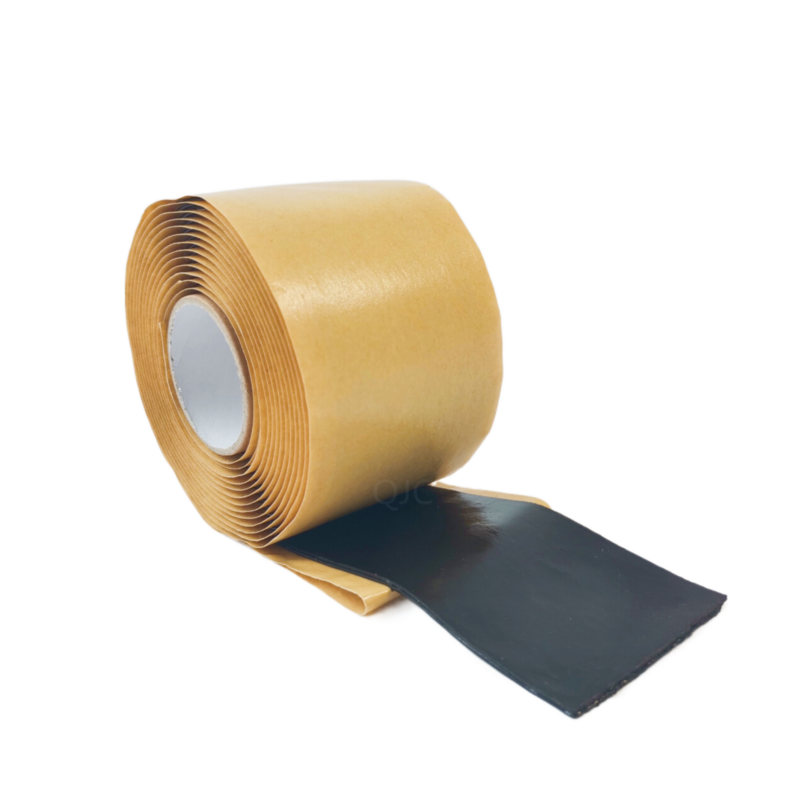

In automotive applications, it can seal fuel lines and hydraulic connections In automotive applications, it can seal fuel lines and hydraulic connections

In automotive applications, it can seal fuel lines and hydraulic connections In automotive applications, it can seal fuel lines and hydraulic connections rubber tape for leaks. In the aerospace industry, it is used to seal gas and liquid lines. Even in household chores, it can be utilized to fix leaky faucets or garden hoses, showcasing its versatility.

rubber tape for leaks. In the aerospace industry, it is used to seal gas and liquid lines. Even in household chores, it can be utilized to fix leaky faucets or garden hoses, showcasing its versatility. Whether it's repairing leaks in roofs, plumbing systems, or even automotive applications, this tape can be swiftly wrapped around the affected area, instantly creating a watertight seal Whether it's repairing leaks in roofs, plumbing systems, or even automotive applications, this tape can be swiftly wrapped around the affected area, instantly creating a watertight seal

Whether it's repairing leaks in roofs, plumbing systems, or even automotive applications, this tape can be swiftly wrapped around the affected area, instantly creating a watertight seal Whether it's repairing leaks in roofs, plumbing systems, or even automotive applications, this tape can be swiftly wrapped around the affected area, instantly creating a watertight seal premium leakage repair waterproof sealant butyl rubber tape.

premium leakage repair waterproof sealant butyl rubber tape.3. Flexibility and Adaptability Butyl rubber is inherently flexible, allowing it to be easily installed and conformed to various roofing shapes and structures. This adaptability makes butyl rubber sheets suitable for both flat and sloped roofs, providing a reliable solution for architects and builders working on diverse projects.

2. Outdoor Furniture Maintenance Whether it's a tear in an outdoor umbrella or a broken patio chair, Flex Tape can help you salvage your outdoor investments without having to replace them entirely.

The Versatile Utility of Flex Tape A Comprehensive Look at Flex Tape White 4x5

Applications of Black Flex Tape

black flex tape

4. Household Uses Beyond repairs, Black Flex Tape can also be used for various household projects. From reinforcing furniture to crafting and creating custom solutions, its strength and versatility make it a handy tool for everyday tasks.

Its adhesive backing, designed for secure adhesion, ensures the tape stays in place even under physical stress or varying temperatures Its adhesive backing, designed for secure adhesion, ensures the tape stays in place even under physical stress or varying temperatures

Its adhesive backing, designed for secure adhesion, ensures the tape stays in place even under physical stress or varying temperatures Its adhesive backing, designed for secure adhesion, ensures the tape stays in place even under physical stress or varying temperatures tape pvc insulation.

tape pvc insulation.In addition to their insulating properties, door bottom seal rubber strips also help to protect floors and carpets from moisture and dirt. By preventing water from seeping under the door, these strips can help to prevent water damage and mold growth. They also help to keep out dust and allergens, improving indoor air quality and reducing the risk of respiratory problems.

When comparing prices for floor marking tape, it is also important to consider the size and quantity needed for your specific project. Buying in bulk can often result in cost savings, but be sure to consider whether you will be able to use all of the tape before it expires or deteriorates.

Understanding PVC Electrical Insulation Tape

An industrial control box is not just an accessory; it’s a critical component in a well-oiled industrial environment, facilitating uninterrupted operations and enhancing safety.

insulation cotton tape.

types of intumescent strips. These strips are frequently used in structural applications, such as steel beams and columns, to provide fire protection and structural integrity.

PVC insulation tape is ideal for low voltage applications. It has various uses which include: insulation, sealing, maintenance, protection, fixing and colour-coding. Our PVC Insulation Tape is available in an assortment of colours to facilitate colour-coding for safety and identification purposes.